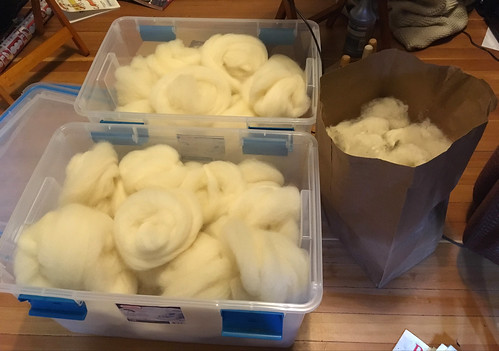

Oh hello, remember me? I've been playing with fiber. There's a big pile of spun yarn that is yet to be photographed, but what I want to show tonight is this fleece that I finally got around to processing.

This is actually half a fleece, purchased at the 2016 Columbia Gorge Fiber Festival, from a full fleece that I split with a friend. It's from Lopez Island, Washington, and if I remember correctly it's a mixed breed dominated by Romney and Blueface Leicester, with lesser amounts of East Friesian, Coopworth, Columbia, Dorset, and North Country Cheviot genes in the flock. It's been sitting in the closet for over a year, and this week was finally its turn to shine.

I washed it in two evenings, just in my kitchen sink in dishpan-sized batches. It wasn't overly greasy, but the tips were pretty gunked up with hardened lanolin and dirt.

After one hot soapy soak and two hot rinses, the wool became a lovely creamy white and all the grease was out. Some of the tips were still a little dirty and clumpy, but not too bad. They opened right up during combing.

So here's the before and after. Washed on top, raw on the bottom. The lighting is wonky on this picture, but trust me, there was a big difference. The separate shots above are pretty close to the actual color change.

Once the wool was clean and dry (furnace vents are wonderful for drying wool, if you can keep the cats off), my next step was combing. You load the wool onto one comb and comb it off with the other, during which all the dirt and vegetable matter (bits of hay, etc.) falls out and the fibers are separated and aligned.

This is after two transfers from comb to comb. Puffy and delicious.

Then I used a diz (the round wooden thing with the holes) to draw the fiber off the comb. The diz helps make an even-sized rope of fiber called top. Wind up the top into a little nest, and voila! Ready to store or spin.

That first nest was 20 grams of fiber, with 2 grams of combing waste there to the right. The waste is all the short bits, neps, vegetable matter, dirt, and other undesirable stuff that the combs remove from the good fiber. A combing loss of 9% is pretty good- there wasn't a lot of bad stuff to comb out of this fleece. The finished top is pure spinning bliss.

I combed about half the fiber today, and will get to the rest over the weekend. I love wool.